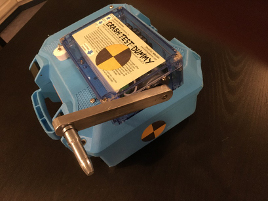

How Tough Is It? – The Water Box Can Take A Beating

by David Holman and Dave Conklin, DayZero Products

We wondered what kind of damage might occur to the water box if it were to experience likely accidental impacts. We tested two scenarios, one where the case slips from the hand of a user while carrying it by the handle, and a second one, where it falls from a greater height like from a counter or a higher shelf.

Here is a summary of our test results. A more detailed description of what we did follows the photo below. When we simulated having the water box slip out of your hand while being carried, we couldn’t break it in eleven drops ranging in height from 21” to 35”, although we did pop off the plastic part of the crank handle on the fifth drop. When we continued to torture that same unit by pushing it off four more times from a high countertop height (43”) it still worked OK. We went higher still, and on the fourth drop from four and a half feet, the unit started to get flaky, taking a few seconds to come fully on, but it was still useable. Finally, after the first drop at five and a half feet the external power circuit quit working; but even then the bulb still lit up using the hand-cranked generator. At that point we rebuilt the circuit and replaced the bulb and crank, but we kept the original tank, generator, and electronics enclosure (our “crash test dummy”) even though it had already been dropped twenty times. We began a second series of tests starting at 43”. It survived six more drops in battered but still working condition before finally succumbing at a height of four and a half feet on its 27th drop. The glass in the bulb never did break.

Scenario 1 was tested by repeatedly dropping the case onto a concrete slab from a height of about 18”. We used a heavy duty gripper arm to hold the case through the handle, which could then be released from a distance, letting the water box fall to the concrete. We dropped the case 5 times at this height before the plastic crank handle broke off of its metal spindle. At this point, the water box was still fully functional since the generator could still be cranked, either by slipping the handle back onto the spindle, or by cranking holding the spindle itself. Small hands wouldn’t have any problem with the latter.

Scenario 1 was tested by repeatedly dropping the case onto a concrete slab from a height of about 18”. We used a heavy duty gripper arm to hold the case through the handle, which could then be released from a distance, letting the water box fall to the concrete. We dropped the case 5 times at this height before the plastic crank handle broke off of its metal spindle. At this point, the water box was still fully functional since the generator could still be cranked, either by slipping the handle back onto the spindle, or by cranking holding the spindle itself. Small hands wouldn’t have any problem with the latter.

We continued handle drops at ever increasing heights using the damaged water box as is. The unit was dropped 6 more times, starting at 21” and finishing at 35” inches, without any further damage. The water box was still fully functional.

Then scenario 2 was tested by pushing the “as is” water box off of a shelf from each of its 4 sides, at increasing heights. A lever was used to push the box off of the shelf without touching it by hand. Four tests at 43” incurred no further damage and the water box was still fully functional. Four more tests at 55” caused the magnet epoxied to the tank to break off. At this point, instead of lighting up immediately and staying on, the bulb was flashing on and off for 2 to 5 seconds before remaining on continuously.

We raised the shelf to 66” and pushed the water box off by the handle side. While there was no obvious new physical damage, following that drop in EXT mode the bulb would only flash every few seconds. In GEN mode, however, the bulb would still fully light up and stay on. The switch nut and crank spindle had also loosened, by less than one turn. When we did an autopsy, we couldn’t identify a circuit failure, but we did discover that at one end of the bulb the ceramic cap had broken loose from the glass tube, while the glass tube itself was undamaged.

We should note here that while we tried to standardize the drops by using simple mechanical means to release or push the test unit, the actual behavior of the unit during the drop varied. Sometimes the handle hung up on one of the gripper fingers before dropping. In the shelf tests, the rubber feet gripped the surface in different ways. As a result, in each drop the test unit rotated somewhat differently while falling.

At this point we realized that we were testing the durability not only of the physical package, generator, and bulb, but also of the other circuit elements. We decided to bring our “crash test dummy” unit up to the circuit construction standards used in our recent production run. We installed a new ballast, rocker switch, printed circuit board, and DC jack into the existing electronics enclosure, put a safety shut-off switch and a new bulb into the existing tank, and attached a new crank arm and handle on the generator shaft.

We repeated the scenario 1 handle drop tests at the maximum height, 35”, used in the first series of scenario 1 tests. There was no new damage and the water box remained fully functional.

Then scenario 2 was repeated at 43”, pushing from each side. During these four drops the cap magnet broke off, the handle spindle was bent slightly, and the plastic crank handle finally flew off on the last test.

We raised the shelf to 54” and pushed the test unit off from the handle, hinge, and outlet sides. The water box was fully functional after the first two tests, but on the outlet side test the unit landed upside down on the lid of the electronics enclosure, bounced and flipped, and landed a second time on the lid. This put the unit out of service. Examination revealed that the metal ballast case had bent lengthwise between the two mounting screws and was no longer sitting flat on the bottom of the enclosure. Inside, the bulb connector end was free of the lamp holder, while the ceramic cap at the other end of the bulb was still in its holder, but stressed. The glass tube had broken loose from the ceramic end cap, but again, the glass tube itself was undamaged. The crank arm set screw and handle spindle were slightly loosened, and the rocker switch was loose but still retained in its hole.

Replacing the bulb did not restore the unit to a useable condition. We did note that tapping hard on the ballast while in EXT mode would get the bulb to flash on/off briefly during the tap.

Don’t try this at home.